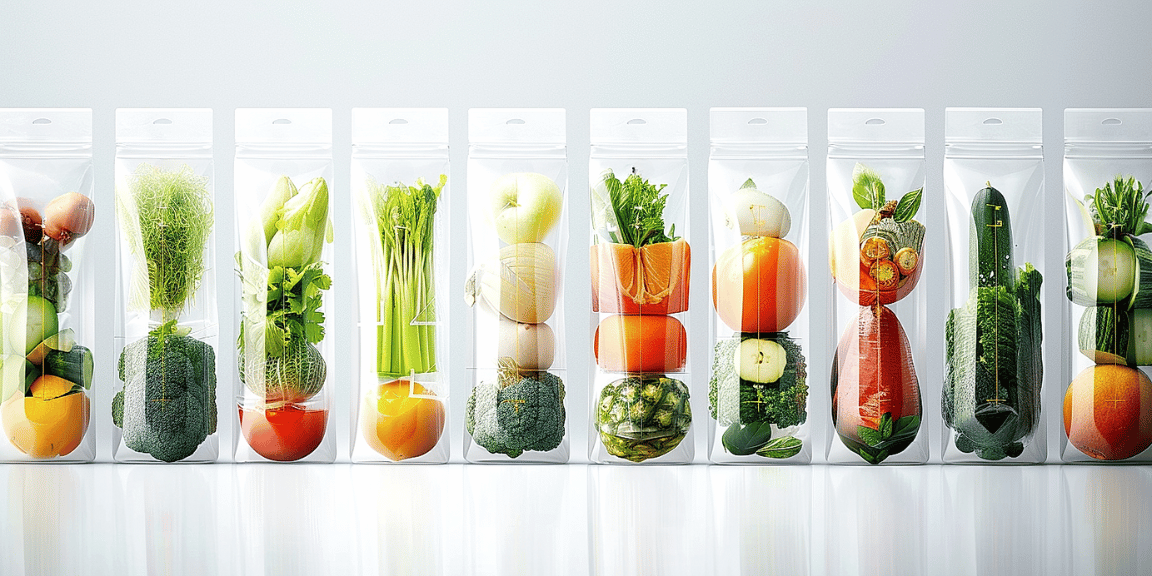

In recent years, robust developments in the arena of packaging have drastically transformed the landscape of produce distribution.

These innovations are not just enhancing the aesthetical appeal, but also immeasurably improving product shelf-life and distribution efficiency.

Given the environmental and sustainability considerations, this is a much-anticipated shift.

This write-up aims to delve into these intriguing advancements and their implications.

It focuses on recently introduced packaging methodologies, their effect on distribution logistics, and the horticultural industry at large.

This dissection will prove insightful for stakeholders seeking to stay abreast of trending shifts within this realm.

Contents

- Packaging Innovations In Produce Distribution

- 1. Biodegradable Cornstarch Packaging

- 2. Edible Coatings for Extended Shelf-Life

- 3. Smart Packaging with Freshness Indicators

- 4. Zero-Waste Reusable Packaging Systems

- 5. Plant-based Plastic Alternatives

- 6. Temperature-controlled Insulation Boxes

- 7. Compostable Bags and Wraps

- 8. Retain Freshness Vacuum-Seal Techniques

- 9. Food-safe Ink Printing on Packaging

- 10. QR Code Embedded Packaging for Traceability

- The Bottom Line

Packaging Innovations In Produce Distribution

1. Biodegradable Cornstarch Packaging

One of the most promising innovations in the field of produce packaging is biodegradable cornstarch packaging.

This cutting-edge solution addresses a multitude of concerns tied to traditional, non-biodegradable plastic packaging, notably the issues of pollution and waste.

As the name implies, biodegradable cornstarch packaging is made from cornstarch, a readily renewable, plant-based resource.

This is a sustainable choice as its production requires less energy and emits fewer greenhouse gases compared to synthetic plastic manufacturing.

The main trait of biodegradable cornstarch packaging is its ability to break down naturally in the environment over time, unlike traditional plastic which can take hundreds of years.

When disposed of properly, cornstarch packaging biodegrades into its basic components of water, CO2, and biomass, resulting in zero waste.

The resulting biomass can even serve as a nutrient-rich food source for the soil, reinforcing the packaging’s environmental credentials.

Additionally, biodegradable cornstarch packaging does not release harmful toxins into the environment as it breaks down, contributing to a healthier planet.

This characteristic positions it as an effective solution against the pollution crisis caused by discarded single-use plastic packaging.

Moreover, cornstarch-based packaging provides excellent protective properties for fresh produce, making it a practical choice for distributors.

Its physical characteristics allow it to retain moisture and prevent the produce from wilting or drying out, thus maintaining product’s freshness.

This is particularly relevant in the grocery sector, as it aids in preserving the appeal and extending the shelf-life of the goods.

Specially designed cornstarch packaging solutions can also incorporate anti-fungal and anti-bacterial properties to further enhance food safety.

The growing public awareness and demand for environmentally-friendly alternatives are likely to support the adoption of biodegradable cornstarch packaging in the produce distribution industry.

However, cost considerations and the specifics of mass production still present challenges to overcome before this eco-friendly packaging can become mainstream.

A shift towards renewable, biodegradable, and environmentally-friendly packaging like cornstarch packaging will greatly contribute to sustainable production and distribution within the food industry.

2. Edible Coatings for Extended Shelf-Life

Preservation of food items stands as a major concern for the food industry and packaging plays a significant role in this.

One innovation that is creating waves in this field is the development of edible coatings to extend the shelf-life of fresh produce.

This remarkable solution is helping the industry in reducing waste and improving cost efficiency.

Edible coatings are biodegradable, safe for consumption, and environmentally friendly.

Edible coatings function by forming a thin layer around the food product that helps to slow down the degradation process.

This innovative material is typically made from proteins, polysaccharides, lipids, or a combination of these.

These food-grade substances when applied to produce, create a barrier to moisture, oxygen, and microorganisms that cause spoilage.

This protective layer helps to maintain the freshness, quality, and nutritional value of the product for a longer period.

The composition of the coating can be customized according to the requirements of the specific food product– some coatings may be enhanced with antimicrobial compounds or antioxidants to further prolong the shelf-life.

Moreover, edible coatings can improve the taste and aesthetic appeal of the produce as they can carry flavors or colors.

Not only that, but they can also be infused with nutritional supplements and functional compounds to enhance the nutritional value of the covered products.

Besides, the utilization of edible coatings presents a promising alternative to plastic packaging, subsequently reducing the ecological footprint that conventional packaging methods impose.

Sophisticated technologies such as nanoemulsification or electrospraying are being used to apply these coatings to ensure uniform coverage and optimal performance.

Even though there are logistical challenges tied to the utilization of edible coatings, like scaling it up for commercial use or developing proper transport and storage strategies, the potential benefits and environmental savings justify the continuous research and development in this sector.

The beauty of edible coatings lies in their potential to revolutionize food packaging; the possibility of safer, more sustainable solutions that cater to the world’s ever-growing food demands.

3. Smart Packaging with Freshness Indicators

One of the most cutting-edge innovations in the field of produce distribution is the rising implementation of smart packaging with freshness indicators.

These are intelligent systems that are capable of revealing the freshness levels of the products within their packaging.

By integrating biochemical or digital indicators in the packaging, they communicate information about the produce’s state to consumers, retailers, and suppliers.

One of the prime benefits of such an initiative is the increase in consumer confidence for the integrity of the product they purchase.

The exact and real-time data presented by these smart packages allow consumers to make well-informed choices, about their food purchases.

Not only does this reduce unnecessary food wastage, but it also enforces higher safety standards within the food distribution sector.

Food producers also gain from these freshness indicators as they provide insights into the storage and distribution conditions of their produce.

These readings allow for an optimization of the distribution process, leading to better quality products reaching the consumers.

Furthermore, smart packaging with freshness indicators offer a tangible solution to issues of food spoilage within the supply chain.

These are intelligent systems that are capable of revealing the freshness levels of the products within their packaging.

There are several types of freshness indicators, including time-temperature indicators, gas indicators, and biosensors.

Time-temperature indicators show changes based on storage time and temperature, while gas indicators respond to changes in gases like carbon dioxide or oxygen.

Biosensors, on the other hand, are based on biochemical reactions and can indicate specific spoilage organisms or degradation compounds.

The application of this technology, while promising, does pose certain challenges, such as the of design and cost of these indicators.

Resolving these can allow a wider implementation and greater benefits for all members within the food production and distribution chain.

Overall, smart packaging with freshness indicators represents a revolutionary approach to extend shelf life, ensure quality, and minimize food wastage.

4. Zero-Waste Reusable Packaging Systems

In the world of produce distribution, zero-waste reusable packaging systems are growing in popularity due to their ecological benefits and logistical efficiency.

These systems employ materials that are either compostable or recyclable, drastically reducing negative environmental impact and waste generation.

Innovatively designed, zero-waste packaging can be used multiple times before they reach the end of their lifecycle.

By making use of long-lasting, recyclable materials, companies can minimize their consumption and the consequent disposal of resources used in packaging.

These packaging systems not only seek to reduce waste but also aim to influence the behaviors of both the food industry and consumers toward more responsible and sustainable practices.

Reusable packaging is also beneficial for consumers, who can repurpose these items for personal use, further promoting zero-waste lifestyle.

The application of zero-waste packaging spans a variety of businesses in the agriculture sector from organic farms, local markets to health food stores.

Larger corporations are also getting on board, integrating reusable packaging strategies into their global distribution networks to lessen their environmental footprint.

Moreover, smart designs have been developed such as collapsible reusable crates which optimise storage and transport space, thereby improving efficiency.

There are also initiatives challenging businesses to design and produce packaging that is completely reusable, recyclable or compostable by a certain date.

Fruit and vegetable distribution businesses, in particular, have ample opportunity to utilise zero-waste reusable packaging systems given the volume and frequency of their transactions.

As technological advancements continue, so too does the potential for more innovative designs of reusable packaging systems that can accommodate a variety of produce types.

These advancements are pushing the boundaries of what is possible in terms of sustainability and efficiency in the realm of produce distribution.

Both the social and environmental benefits of zero waste reusable packaging systems promise a more sustainable future for produce distribution.

5. Plant-based Plastic Alternatives

Among the innovations in packaging is the exploration of plant-based plastic alternatives.

This packaging approach helps every participant in the produce supply chain system to demonstrate environmental responsibility.

The plant-based plastic alternatives are environmentally friendly as they are sourced from natural and renewable resources like cornstarch, sugarcane, and PLA (Polylactic Acid), a polymer derived from fermented plant starch.

Unlike conventional plastic, plant-based plastic alternatives are designed to degrade in a matter of months or a few years under certain conditions, rather than a few centuries as petroleum-based plastics do.

PLA plastic, for instance, is both biodegradable and compostable, breaking down into carbon dioxide and water under industrial composting conditions.

Another significant benefit of plant-based plastic alternatives is their potential to reduce the carbon footprint associated with packaging.

With processes that require less energy and produce fewer greenhouse gases than conventional plastic, plant-based alternatives present a viable solution for sustainable packaging.

However, while plant-based plastic alternatives offer significant environmental benefits, they also present challenges.

For instance, although they are compostable, proper composting facilities are not readily available in many regions.

In so doing, without a robust infrastructure for composting, these alternatives might end up in landfills where they release methane, a potent greenhouse gas.

Furthermore, the production of plant-based alternatives might also compete with food crops for land use and resources, raising ethical questions.

What’s more, plant-based plastics often come with a higher price tag compared to traditional plastic, making the transition challenging for some companies due to the cost implications.

Notwithstanding these obstacles, the opportunity for a packaging solution that aligns with the sustainability goals is driving innovation and research into plant-based plastic alternatives.

Companies are exploring the use of non-food crops, algae, and even food waste as possible raw materials for these alternatives.

In conclusion, the innovation of plant-based plastic alternatives contributes to the sustainability of produce packaging and distribution while also presenting new opportunities and challenges that need to be navigated wisely.

6. Temperature-controlled Insulation Boxes

Temperature-controlled insulation boxes are an innovation in packaging that is proving crucial in the distribution of produce.

These boxes have been designed to maintain and regulate the temperature within the packaging itself, safeguarding the freshness of the produce inside.

Fruit and vegetables, for instance, require specific temperature settings to keep them fresh during transportation, and these boxes are able to provide the right environment for each type of produce.

With the fluctuating temperatures in traditional packaging methods, fresh produce can wilt or over-ripen, but temperature-controlled insulation boxes mitigate this problem by maintaining an ideal climate.

By having a stable, regulated temperature in the packaging, producers can significantly reduce the amount of food waste that results from improper storage and transportation conditions.

These boxes also protect against outside temperature fluctuation, maintaining the internal conditions even when there is extreme cold or heat outside.

The insulation material used in these boxes is often made from eco-friendly material, contributing further to the sustainability goals of the produce industry.

Overall, they are an effective solution for the safe and efficient transport of fresh produce from the farm to the consumer’s table.

Apart from keeping produce fresh, these boxes are also ideal for delivery of temperature-sensitive products, such as pharmaceuticals, vaccinations or other health products.

The use of these boxes not only extends the shelf-life of the produce, but can also potentially expand the geographic market area for suppliers.

By maintaining optimum temperatures, these innovative boxes also conserve the nutritional value of the produce, which might be lost under less ideal storage conditions.

Temperature-controlled insulation boxes are not only a packaging innovation but also a cost-effective solution to a myriad of issues involving produce distribution.

Considering their widespread potential benefits, there is a growing trend toward incorporating temperature-controlled insulation boxes into distribution strategies in the produce industry.

They exhibit a promising example of how packaging can play a significant role in not only preserving food but also reducing waste and supporting sustainability efforts.

In summary, temperature-controlled insulation boxes are a necessary innovation for improving the quality, efficiency, and sustainability of produce distribution.

7. Compostable Bags and Wraps

One of the most revolutionary advancements in modern packaging has been the development of compostable bags and wraps.

These are products made from materials that break down and decompose in a composting environment, typically within a few months.

This is in stark contrast to conventional plastic bags and film wraps that cause enormous damage to the environment, taking hundreds of years to decompose in landfill sites.

Compostable packaging solution, as the name suggests, degrades in a compost pile or industrial composting facility, becoming nutrient-rich compost.

The use of compostable bags and wraps in the produce distribution industry can present a solution to various environmental issues linked with plastic waste.

This trend towards sustainability and ecological responsibility in packaging points towards a future where unnecessary waste could become a scenario of the past.

These innovative products come in various types suitable for different produce, such as fruits, vegetables, grains, and other perishable food items.

The materials used to produce compostable bags and wraps are usually plant-based, such as cornstarch, potato starch, and other organic matter.

While the exact composition might vary among different producers, the fundamental principal is the capability to break down in a compost heap.

Considering the massive amounts of plastic waste produced from food packaging each year, the shift towards compostable packaging can make a significant impact on environmental preservation.

Furthermore, organizations involved in produce distribution can adopt these packaging methods to showcase their commitment to environmental sustainability.

This shows the potential customers that these organizations are doing their share to combat the environmental crisis, thus enhancing their brand image and reputation.

It can provide a competitive edge in the increasingly eco-conscious consumer market.

However, while compostable bags and wraps present obvious benefits, it is crucial to ensure that they are properly composted after use to prevent them from behaving like conventional plastic in a landfill.

It is also important to educate consumers and businesses about the necessity of correct disposal for these compostable materials.

Undoubtedly, compostable bags & clings are hallmark advancements that are making the journey towards a greener, sustainable future a tangible reality.

8. Retain Freshness Vacuum-Seal Techniques

One of the most innovative advancements in produce packaging is the utilization of vacuum-seal techniques that ensure the retention of freshness.

These techniques act as a barrier against oxygen and moisture, which are known to speed up the process of food degradation.

By preventing these elements from contacting the product, the shelf-life of the produce is greatly extended.

The vacuum-seal technique primarily involves the removal of air from the package before it’s sealed.

This complete removal of air ensures that no bacteria or fungi, which require air to grow, can survive in the package.

Another advantage is that vacuum sealing also helps in preserving the taste and aroma of the product, which are often lost in other packaging methods.

This is because there is no exchange of odours between the packaged food product and the external environment.

Moreover, the vacuum-seal methods can be combined with modern technologies like Modified Atmosphere Packaging (MAP) to improve the preservation process.

In MAP, once the air is removed from the package, it is replaced with other gases like nitrogen and carbon dioxide, which do not support the growth of bacteria or fungi.

Apart from extending shelf-life, vacuum-sealed produce packages also reduce the volume of the packaged products, which makes them easier to handle and store.

This not only reduces storage costs but also minimizes the carbon footprint associated with the transport of the products.

Furthermore, vacuum sealing helps in preventing freezer burn for produce that needs to be frozen.

It does so by keeping the cold air away from the surface of the produce, thereby preventing the loss of colour, texture, flavour, and nutritive values.

In the ever-evolving field of packaging, vacuum-seal techniques have proved to be a game-changer, proving indispensable for distributors who aim to deliver fresh and high-quality produce to the market.

However, it’s crucial for the packaging industry to further innovate and improve these techniques with environmentally friendly methods to ensure sustainability.

9. Food-safe Ink Printing on Packaging

Printing on packaging has evolved from being a means to include brand logos or product information, to now being a way to strengthen food safety and enrich user experience.

One of such innovations is the development and use of food-safe ink in packaging printing.

Food-safe ink, as the name implies, is an ink specifically designed for food packaging that meets international food safety standards.

The primary concern for any printing on food packaging is inks potentially contaminating the food product inside.

Thus, food-safe inks are formulated to ensure that even if there’s accidental migration, the constituents of the ink don’t pose a health risk.

Their formulation often involves excluding substances like heavy metals, certain aromatic amines, allergenic dyes, etc. which are potentially harmful if ingested.

Furthermore, food-safe inks come with certifications from regulatory bodies such as the FDA (Food and Drug Administration), BfR (German Federal Institute for Risk Assessment), Swiss Ordinance, and others to confirm their safety levels.

Using food-safe inks benefits both producers and consumers. For producers, these inks can protect them from potential legal liabilities associated with food contamination.

If food gets contaminated through the packaging, it could lead to product recalls, public backlash, brand reputation damage, and potential legal consequences. These risks are significantly reduced with the use of food-safe inks.

For consumers, packaging printed with food-safe ink provides an added assurance of safety when purchasing a product.

The development and use of food-safe inks represent innovation in the packaging industry with a clear focus on food safety.

It’s also likely that in the future, with further advances in technology, we may see more functionalities added to these inks, such as detection capabilities for detecting food freshness or spoilage.

However, it’s important to note that the use of food-safe inks is just one component of ensuring complete food safety in packaging.

Other factors like the material of the packaging, the printing process used, environmental conditions, storage conditions, etc., also play a critical role.

To conclude, food-safe ink printing on packaging symbolizes an innovation that not only elevates the aesthetic appeal of packaging materials but also significantly contributes to food safety, a crucial aspect in the produce distribution chain.

10. QR Code Embedded Packaging for Traceability

The concept of QR code embedded packaging represents one of the advanced packaging innovations in produce distribution.

As consumers increasingly demand transparency in the food supply chain, this technology offers a viable solution to ensure produce traceability.

QR codes, when scanned with a smartphone, provide critical information about the product including its origin, handling, and processing details.

The use of QR codes for traceability purposes is transforming not just the packaging sector but also the food and agriculture industries.

One of the main benefits of QR code embedded packaging is that it enhances food safety by enabling quick recall of contaminated products.

It identifies the source of contamination swiftly ensuring timely resolution and prevention of widespread outbreaks.

Moreover, QR code embedded packaging empowers consumers by giving them access to vital information about their food, fostering accountability in the food industry.

This technology also aids in curbing food fraud by ensuring that the products are exactly what they claim to be.

By embedding QR codes, producers can authenticate their products thereby building trust with discerning consumers who are willing to pay a premium for verified produce.

Apart from traceability and authenticity, QR code embedded packaging provides immense marketing advantages to merchants.

They can guide consumers to their website, offer discount codes or share exciting recipes related to the product to enhance shopper engagement, providing an interactive shopping experience.

It is, therefore, not surprising that leading retailers, supermarkets, and produce sellers are adopting QR codes in their packaging strategy.

Despite its numerous advantages, it’s important to note that the success of QR code embedded packaging relies heavily on the willingness of consumers to scan the codes and their access to the required technology.

In response to this challenge, stakeholders are exploring ways to encourage consumer interaction, such as incorporating eye-catching designs around the QR code and educating the public about their benefits.

Moreover, packaging designers are coming up with innovative ideas to integrate QR codes aesthetically on product packages, enhancing the visual appeal while retaining the functionality.

Undeniably, QR code embedded packaging is a breakthrough that merges technology with packaging, providing an effective tool for traceability, consumer engagement, and the promotion of a transparent food supply chain.

The Bottom Line

With an ever-increasing demand for sustainable and responsible consumerism, innovation in food packaging is pivotal.

From biodegradable cornstarch packaging and edible coatings that extend shelf-life, to smart packaging with freshness indicators, each solution is striving towards minimal environmental impact.

Zero-waste reusable packaging systems and plant-based plastic alternatives are pushing boundaries for a greener future, supplemented by the feasibility of temperature-controlled insulation boxes.

Compostable bags and wraps, along with freshness retaining vacuum-seal techniques, revolutionize the way we transport and store food.

The incorporation of safe ink printing and QR code embedded packaging not only optimizes consumer safety but also enhances traceability.

These advancements blend sustainability with functionality, shaping the future of the food industry.